Why Knock Down Packing Is the Smart Solution for Furniture Shipping

Shipping furniture across cities — or even internationally — requires careful planning, especially when it comes to packaging. This is where the knock-down packing concept comes in: an efficient, practical solution increasingly favored by both manufacturers and customers. But what exactly makes this system so popular? Let’s find out!

What Is Knock-Down Packing?

Knock-down packing is a packaging method where furniture is shipped in an unassembled condition. Components such as panels, racks, or frames are carefully arranged to save space and make transportation easier. This approach significantly reduces the risk of product damage during shipping.

Why Knock-Down Packing Is the Right Solution

1. Space and Shipping Cost Efficiency

Because the furniture is shipped in separate parts, its total volume is much smaller than if it were fully assembled. This saves valuable space in trucks or containers and directly lowers shipping costs.

2. Lower Risk of Damage

Knock-down packing minimizes protruding parts or vulnerable sections that could be damaged during transport. Each component can be wrapped in protective materials like foam sheets, thick cardboard, or wooden crates — offering better protection against scratches or breakage (especially for glass components).

3. Easier Distribution

For large-scale deliveries to multiple locations, the knock-down system offers greater flexibility. For example, one container can carry furniture for several branch stores at once.

4. Environmentally Friendly

Smaller packaging sizes mean less packing material is required. This helps reduce waste and lowers the carbon footprint from transportation processes.

5. Supports Large-Scale Production

For manufacturers, the knock-down system improves quality control and production efficiency. Furniture can be assembled directly at the destination by technicians or even customers, with the help of simple assembly instructions.

Challenges and How to Overcome Them

While efficient, the knock-down system requires precise design and production planning. Component joints must be strong and easy to reassemble without special tools. That’s why high-quality materials, reliable locking systems, detailed assembly guides, and even installation videos are essential to maintaining the quality of knock-down furniture.

Conclusion

In the world of furniture logistics and distribution, knock-down packing isn’t just a trend — it’s a proven solution for cost efficiency, product safety, and shipping convenience. This system allows furniture to be packed more compactly without compromising quality or functionality.

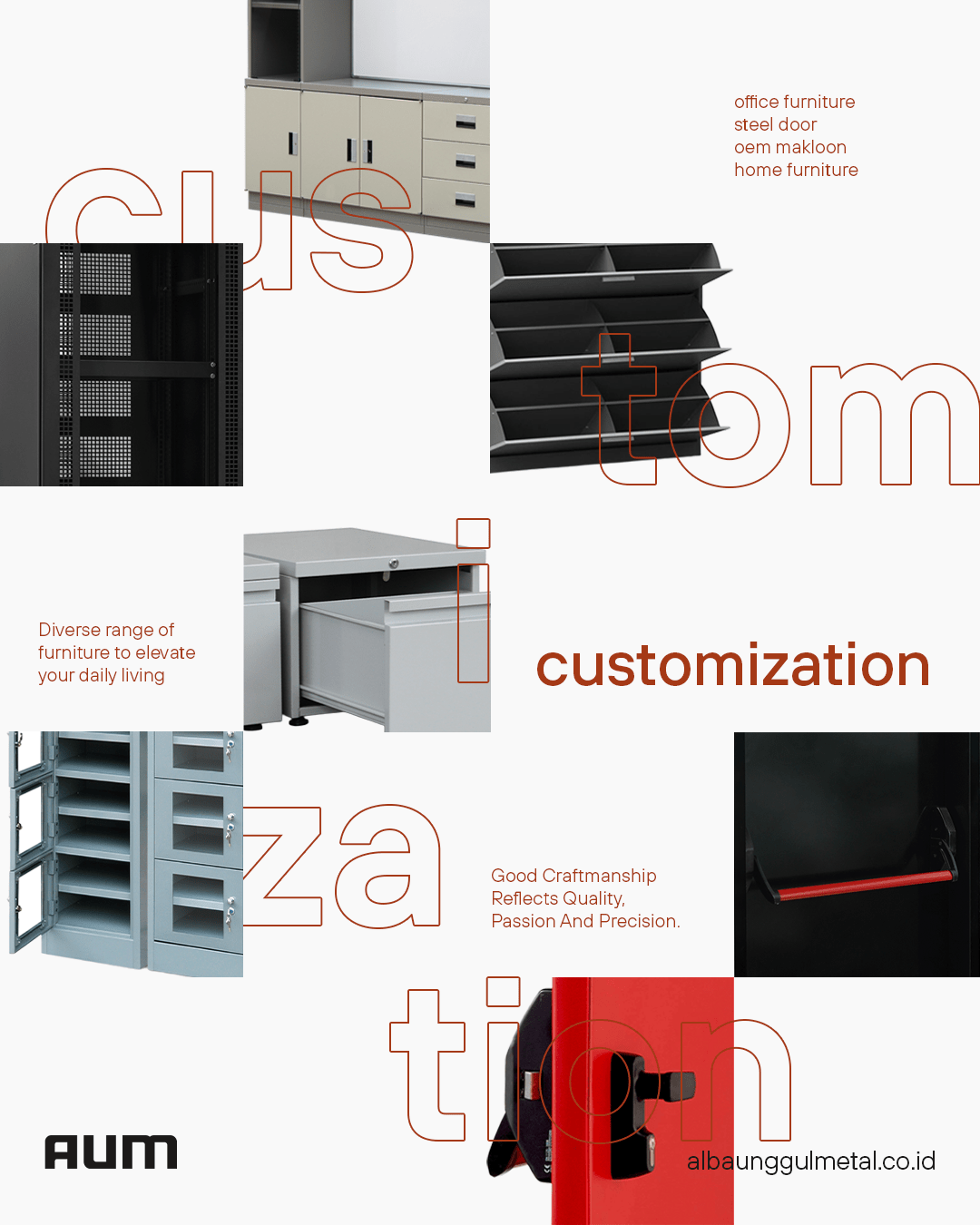

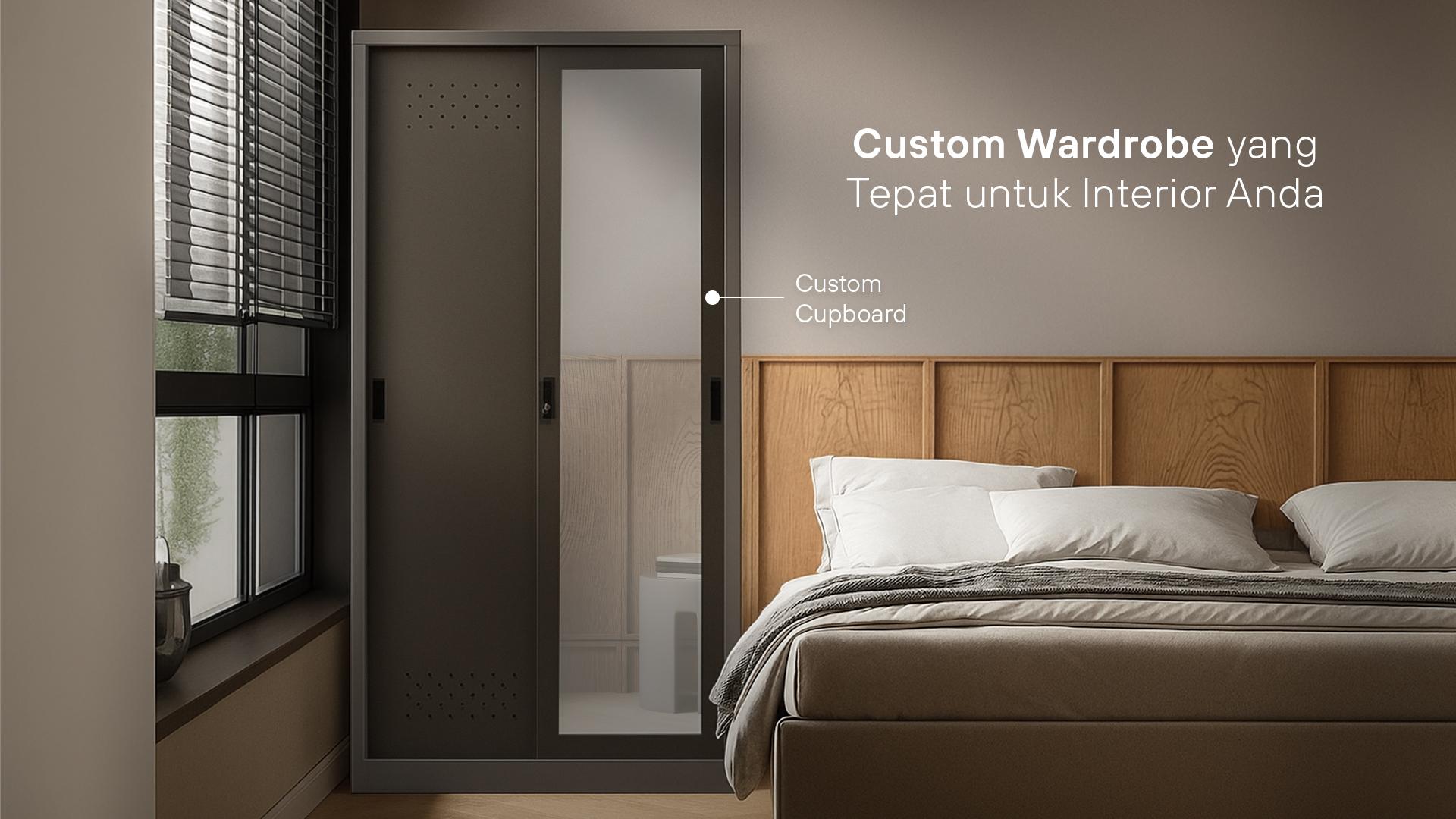

Alba Living stands as a trusted partner for custom metal furniture with a reliable knock-down system. With precise design, durable materials, and professional production processes, we ensure every product is ready to ship safely and efficiently — whether domestically or internationally.

Need custom metal furniture with a knock-down system for your next project?

Contact Alba Unggul Metal today for a free consultation and get the best offer!